- Home

- About us

- Product

- Back lining bearing

- Four row taper roller bearing

- Four row cylindrical roller bearing

- Double row cylindrical roller bearing

- Double row angular contact ball bearing

- Single row angular contact ball bearing

- Four point angular contact ball bearing

- Double row taper roller bearing

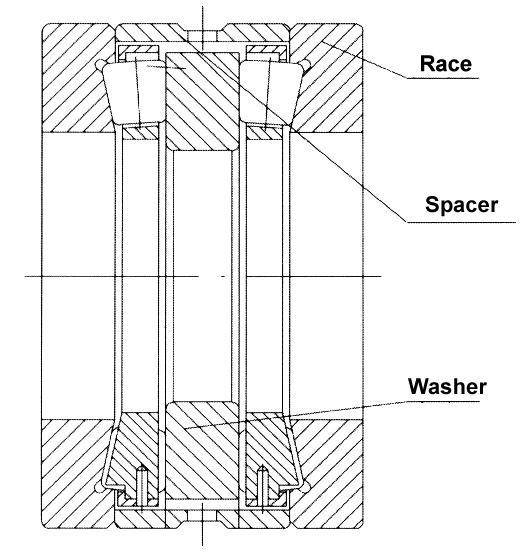

- Double row thrust taper roller bearing

- Deep groove ball bearing

- Product Catalog

- Technical

- News

- Contact us

- 中文

Service

Service