3.Installation guide of bearing for back-up roll

1.assembly stress diagram

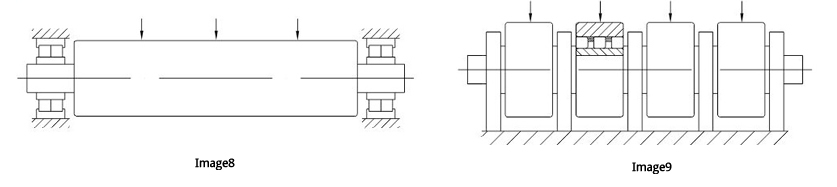

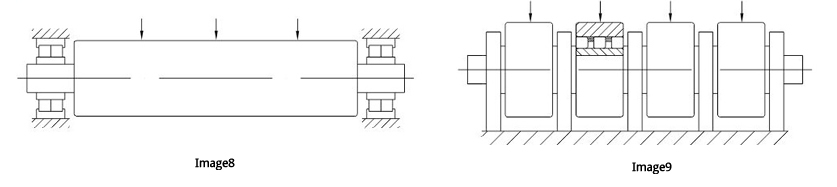

The back-up roll used as a cold rolled sheet multi-roll mill is used with a

backing bearing which is different from the general bearing . The bearings are mounted on either ends of the shaft or roller. The cold rolled sheet multi-roll mill backing bearing is subjected to the action force of the roll itself , load support is supported by a bearing saddle mounted between the bearings. (Image8, Image9)

2. Complex wall thickness management

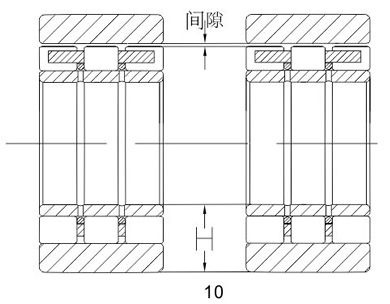

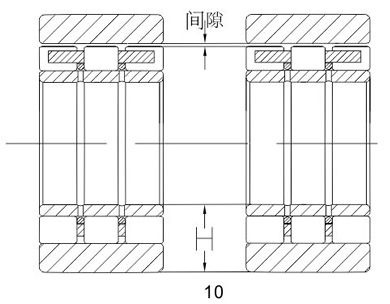

(1) the meaning of Complex wall thickness management (H):

As shown in Figure 10, the radial clearance is zero, and the total wall thickness of the outer ring, inner ring and roller is adjusted.(The bearing must have a radial clearance. If there is no radial clearance, it will cause poor rotation, but the Complex wall thickness refers to the total value of the wall thickness of the outer ring, inner ring and roller after removing the clearance.)

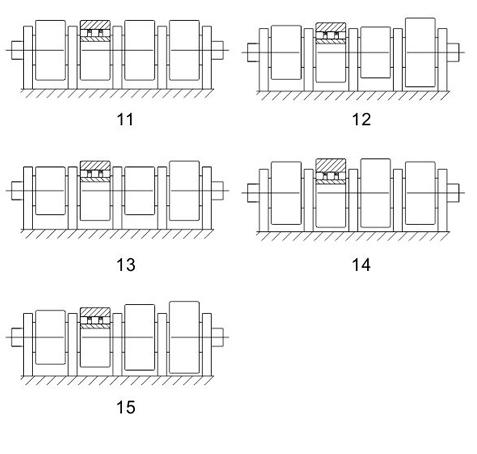

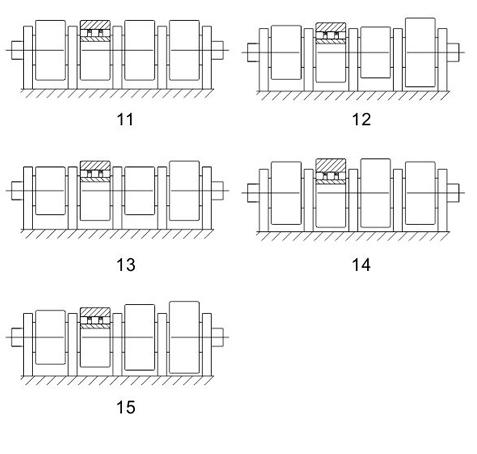

(2) The importance of Complex wall thickness management

As shown in Figure 9, because of the role share of bearing as a roller, if when ta shaf is provided with a few sets of bearings with different sizes, the roll will appear bump, can not play the role of itself.If the bearings on a shaft are shown in figure 11-, Figure 15, the assembly sequence of figure 12,13,15 is not possible.Only the data from Figure 16 detected by the instrument can be used.

Service

Service